Joining the IIoT Revolution

Sophisticated Technologies and Solutions for Industry 4.0 Applications

NEW! IIoT Starter Kit

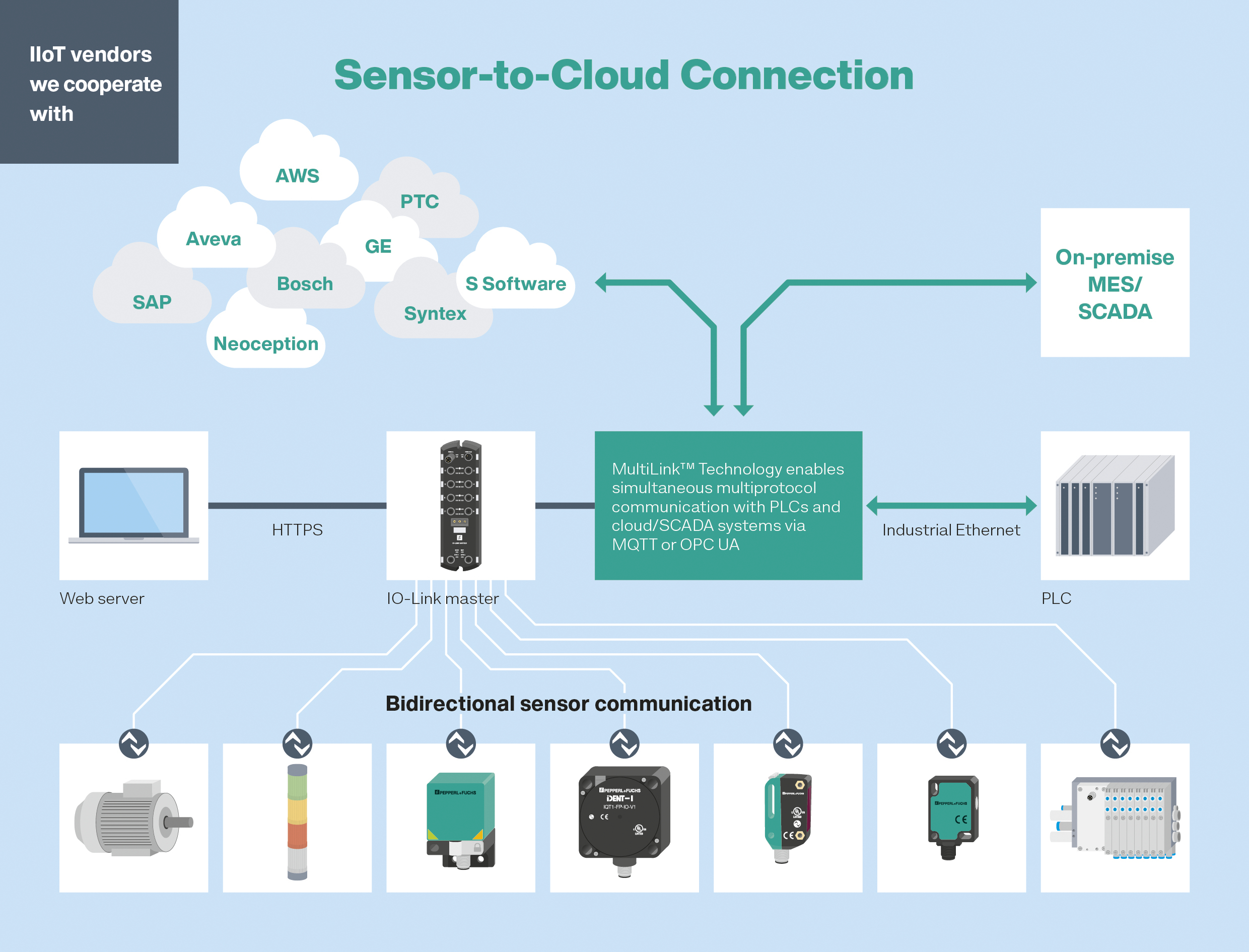

Connect Factory Floor Sensors to the Cloud and Start the Digital Transformation of Your Plant!

With the new IIoT starter kit and the user-friendly IO-Link masters from Pepperl+Fuchs simple visualization and analysis of sensor data become a reality. Discover the advantages of IO-Link and experience the seamless integration of IO-Link sensor data into your Industry 4.0 application.

The kit includes among others:

- An IO-Link master, (3) IO-Link sensors, an Ethernet switch, a power supply, RFID tags and all the necessary cabling to get started

- A quick start guide for connecting the IO-Link master and IO-Link devices

- Software connection for various platforms such as AWS, PTC, AVEVA

Connect your software dashboard via OPC UA or MQTT for easy interpretation of real-time data and start the digital transformation of your plants now with the new IIoT starter kit from Pepperl+Fuchs!

The Industrial Internet of Things (IIoT) thrives on the most comprehensive sensor information possible from the field level. As a specialist and pioneer in the field of factory and process automation, Pepperl+Fuchs recognized this early on and dedicated itself to the fourth industrial revolution with full innovative power under the term "Sensorik4.0®".

Today, we offer end-to-end solutions to seamlessly transfer the valuable information from your machines and plants to a wide variety of software systems. Use the potential of condition, position and availability data, optimize your processes and save resources. This website shows you how to implement this together with us.

Get an insight and do not hesitate to contact us for the realization of your Industry 4.0. application. Our experts are looking forward to your request!

Sensorik4.0®—Joining the IIoT Revolution

Four Layers for Your Success

2. Technologies

3. Components

4. Integration

1. System Design

Plants, products, and systems are becoming increasingly networked. This has resulted in a major effort to set machine-to-machine (M2M) communication standards. IIoT protocols such as OPC UA, MQTT and REST API make this type of communication possible, as well as the implementation of hybrid systems consisting of a PLC and a cloud.

This section presents different IIoT applications to show you how the transition from control-based applications to hybrid or full IIoT applications without superior PLC can succeed.

Hybrid vs. Full IIoT Solutions

The IO-Link masters of the ICE2 and ICE3 series form the basis of hybrid and full IoT applications. Lukas Pogoda, expert for industrial communication, shows you the differences and functionalities of hybrid and full IIoT solutions using various examples. Furthermore, he explains the role played by the IO-Link masters from Pepperl+Fuchs.

Three IIoT Applications

In the animations, you can see three customer-specific IIoT applications that have been realized with Pepperl+Fuchs components: the final assembly of an automotive production line, smart waste management, and a sensor system for detecting leaks at wine and whiskey barrels.

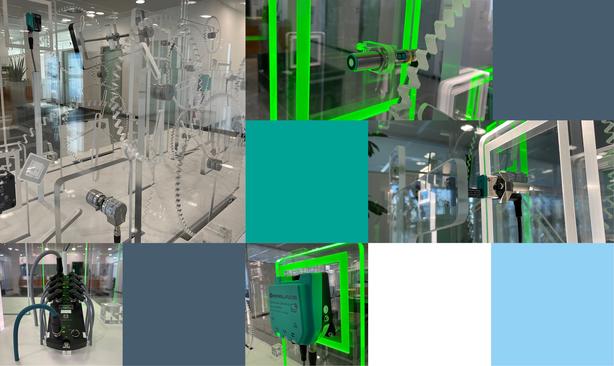

IIoT Demonstrator

The "transparent machine" as a IIoT demonstrator shows how easily data from a wide range of Pepperl+Fuchs sensors can be transferred from the field level to the cloud. Once there, the aggregated sensor data is visualized in a dashboard to generate condition-based alarms, for example. Pepperl+Fuchs will be happy to support you in planning and selecting the appropriate components, infrastructure and software for your individual IIoT solution.

The "Transparent Machine"

In the video, Lukas Pogoda and Jörg Nagel introduce you to the components of the "transparent machine", consisting of hardware from Pepperl+Fuchs and software from Neoception. Here you will learn how sensor data can be transferred to the cloud, displayed and analyzed.

2. Technologies

All around us we hear buzzwords like Industry 4.0, IIoT, smart factories and smart devices. The core concept of this new technological era is the connectivity of every single device. That means that they should communicate in a vendor-independent, standardized, scalable, IT- and OT-ready, interoperable, and secure way. This can only be achieved using smart IIoT communication protocols such as OPC UA, MQTT or REST API.

This white paper compares the different TCP-based communication protocols that have found their way up and are considered the enablers of IIoT and Industry 4.0.

Our expertise spans a wide range of different communication technologies and standards. This diversity allows us to successfully cover any application requirement.

OPC UA, MQTT and REST API Explained

In this video, Lukas Pogoda takes a closer look at the IIoT protocols OPC UA, MQTT and REST API, showing you the advantages and disadvantages of each protocol and which solution is best suited for which application.

Interview: Industrial Communication Protocols for IIoT

IIoT protocols are just as varied as the use case—learn more about the different IIoT protocols and how Pepperl+Fuchs is responding to the constantly evolving requirements in this interview with Sebastian Stöber, R&D Team Leader at Pepperl+Fuchs.

NEW! AWS Partner Qualified IO-Link Masters

Publishing process and status data from sensors to cloud applications in manufacturing plants is one of the key requirements for the IIoT and Industry 4.0 principles. With the official qualification of the ICE2 and ICE3 IO-Link masters as “AWS Partner Devices”, Pepperl+Fuchs is offering users in the AWS ecosystem access to a broad portfolio of sensors for their predictive maintenance and condition monitoring applications.

These fieldbus modules not only support real-time fieldbus protocols (Ethernet/IP or PROFINET) for the connection to deterministically operating industrial controllers, but also offer a completely web-based configuration concept and OPC UA, MQTT and REST API communication. This makes it possible for users without knowledge of fieldbus systems and PLC programming to implement stand-alone applications quickly and easily.

Thanks to the multilink technology, hybrid approaches can be implemented, in which the PLC runs time-critical processes and aggregated status data is transmitted in parallel via OPC UA or MQTT to AWS-hosted systems (e.g. by GE Digital or by Syntax).

3. Components

Some of Our Latest Developments

As a market leader for industrial automation technology, Pepperl+Fuchs offers a wide variety of Industry 4.0 suited sensors, interface components and even mobile devices.

Have look at a some of the latest developments from our portfolio:

4. Integration

IT/OT convergence becomes reality in applications where our dedicated products are used to implement Industry 4.0 technologies. The support of standardized protocols and interfaces as well as built-in software connectors allow for seamless integration in existing IT structures and platforms. Software-based services provided by our IT partners create additional value for our customers.

IIoT Vendors We Cooperate With …

The energy consumption of a hydraulic press can cost manufacturers several thousand euros per year. A significant amount of this energy is used during the static pressing of sintered components. LCM GmbH has developed a system that can help solve this problem. They combined it with sensors and infrastructure components from Pepperl+Fuchs to create a digital hydraulic approach.

Learn More

Together with its partners SAP and Smart City Solutions, Pepperl+Fuchs has developed a custom solution that utilizes ultrasound technology and LoRaWAN® in order to enable smart, on-demand emptying of waste disposal containers in the city of Heidelberg, Germany.

Learn More

The automation specialists Staudinger use SIL 3/PL e suited camera systems from Pepperl+Fuchs to keep their state-of-the-art automated guided vehicles safely on track. This allows the company to supply customers with a complete solution comprising the control and drive technology plus the vehicle itself from a single source.

Learn MoreContact Us

Do you have questions about the Sensorik4.0® solutions from Pepperl+Fuchs? Do you want to receive more information? We are happy to help! Simply fill out the contact form to send us a message.

Downloads

Downloads

+49 621 776-0

+49 621 776-0